Understanding ANSI Cut Levels is vital to ensure your workforce is adequately protected with the appropriate level of cut resistance. To aid you in this process, we have compiled a comprehensive guide, designed to empower you with the knowledge needed to make informed decisions when selecting the right protective workwear for your team.

What is the American National Standards Institute (ANSI)?

The American National Standards Institute (ANSI) is a non-profit organization in the United States that oversees the creation, publication, and use of thousands of norms and guidelines that directly impact businesses in nearly every sector. In the context of Cut Levels, ANSI is known for its role in coordinating the development of standards and ensuring their widespread acceptance and compliance. These standards ensure the safety, reliability, and efficiency of products, services, and systems.

Understanding the Role of ANSI in Standard Development and Compliance for Cut Resistance

In 2016, the American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA) made a significant update to the ANSI/ISEA 105 standard for cut resistance. This update was not just significant in the United States but globally, including the UK and has redefined the parameters for selecting cut resistant gloves and garments.

Before delving into the specifics of the 2016 update, it’s essential to understand the context and cause for the change. The original ANSI/ISEA 105 standard used a 5-level scale and was established to provide a uniform metric for assessing the cut resistance of protective gloves. However, as materials advanced and manufacturing techniques evolved, it became evident that a granular scale was required to accurately reflect the capabilities of newer, more advanced materials such as Cut-Tex PRO®. It should also be noted that although the ANSI/ISEA 105 standard is used to assess the cut resistance of protective gloves and sleeves, it can also be used to assess the cut resistance of all garments and materials such as our Cut Resistant Clothing.

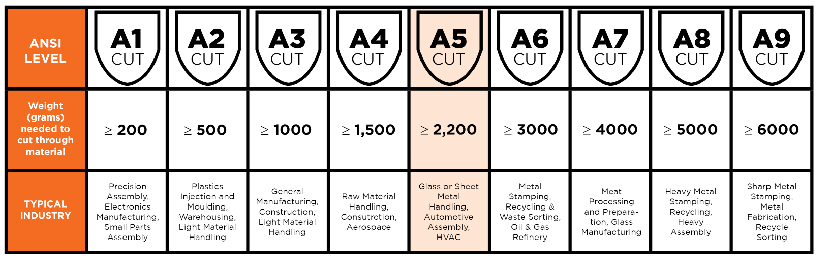

A Closer Look at the 9 Levels of Cut Resistance

The most notable change in the ANSI/ISEA 105-2016 standard was the expansion of the cut resistance scale from 5 to 9 levels. This shift was primarily to address the broad range covered under the previous Level 4, which spanned from 1500 to 3499 grams of cut protection. Due to the wide range, it became challenging to differentiate materials that were at the lower or higher end of this spectrum. For example, a Level 4 with 1500grams of cut protection would be less effective than a Level 4 with 3000 grams of cut protection. Therefore, the new 9-level scale offers a much more detailed classification, allowing for a precise match of glove and garment capabilities which can be applied to the specific needs of various tasks and industries.

How ANSI Cut Levels are Tested:

At the core of the 2016 revision is the adoption of the ASTM F2992-15 test method, which includes the use of the TDM-100 test. This method classifies cut resistance on a detailed scale ranging from A1 (least resistant) to A9 (most resistant).

In the TDM-100 test, a straight-edge blade, under a specific load, moves across the material. The force required to cut through the material at a standardised length is measured in grams. This force corresponds to each level, with higher grams indicating stronger resistance. For instance, a material that requires a greater force to be cut will achieve a higher ANSI cut level. This precise measurement is critical for industries such as metal fabrication, glass handling, and construction, where the risk of cuts can vary significantly based on the nature of the task.

The TDM-100 test ensures a granular and accurate classification of materials, allowing for a more nuanced selection of protective gear based on the specific cut risks present in different work environments.

The Detailed Breakdown of ANSI Levels:

- Level A1 (200 to 499 grams): Best suited for light cut hazards, including tasks like precision assembly and electronics manufacturing, where there is minimal exposure to sharp edges.

- Level A2 to A3 (500 to 1,499 grams): Recommended for moderate cut hazards, typical in automotive assembly and general construction, involving materials with sharper edges.

- Level A4 (1,500 to 2,199): Tailored for high cut hazards, common in industries such as bottle and glass handling, oil & gas, and light metal work.

- Level A5 (2,200 to 2,999 grams): Specifically designed for high cut hazards, ideal for metal fabrication environments.

- Level A6 (3,000 to 3,999 grams): Optimal for extreme cut hazards, frequently found in recycling processes.

- Level A7 (4,000 to 4,999 grams): For extreme cut hazards, particularly in heavy metal stamping operations.

- Level A8(5,000 to 5,999 grams): Excellently suited for extreme cut hazards, such as those encountered in meat processing.

- Level A9 (6,000+ grams): The highest level of protection for extreme cut hazards, crucial in industries like pulp and paper, blade handling, and float glass manufacturing.

Why ANSI/ISEA 105-2016 is Essential for your Workplace Safety:

In the UK, where workplace safety regulations are stringently enforced, understanding, and applying international standards like ANSI/ISEA 105-2016 is essential. British health and safety managers must navigate these standards to ensure that their personnel are adequately protected against the specific risks present in their work environments. This is particularly relevant for multinational corporations and businesses that source PPE from international suppliers.

The updated ANSI/ISEA 105-2016 standard represents a significant stride in the pursuit of heightened workplace safety. By offering a comprehensive and precise classification system, it empowers safety professionals to make informed decisions, reducing the risk of cut related injuries. As a provider of cut resistant workwear, both in the UK and globally, adherence to these standards remains a cornerstone of our collective commitment to employee safety and welfare.

Expanding the Scope: Understanding EN 388:2016 Standards

While ANSI standards are pivotal in defining cut resistance, particularly in the American market, the European Norm (EN) 388:2016 standards also play a crucial role globally, including in the UK. These standards provide a broader scope of protective qualities, covering not just cut resistance but also abrasion, tear, and puncture resistance.

EN 388:2016 - A Closer Look

- Abrasion Resistance: Rated on a scale from 1 to 4, this measures the material's ability to withstand surface wear from rubbing.

- Cut Resistance (Coupe Test): Initially rated from 1 to 5, this test has been supplemented by the TDM-100 test (similar to ANSI) due to the development of high-performance materials.

- Tear Resistance: This is rated from 1 to 4 and assesses how well the material can resist tearing.

- Puncture Resistance: Also rated from 1 to 4, this measures the material's ability to withstand a puncture by a pointed object.

2016 Updates and TDM-100 Inclusion

The 2016 update to the EN 388 standards introduced the TDM-100 test for cut resistance, aligning it more closely with the ANSI standards. This addition allows for a more accurate assessment of cut resistant materials as opposed to just performing the ‘Coupe Test’. The ISO 13997 also known as the “TDM-100 Test” is similar to the ASTM F2992-15 test method which as mentioned earlier is used in the ANSI 105 standard to test cut resistance.

Our Cut-Tex® PRO fabric that is utilised in all our CutPRO® Cut Resistant Workwear has the following cut levels for these standards:

- ANSI/ISEA 2016: Level A5

- EN 388:2016: Cut Resistance (TDM-100 Test) Level E

- EN 388:2016: Tear Resistance Level 4

- EN 388:2016: Puncture Resistance Level 4

- EN 388:2016: Abrasion Resistance Level 3

Balancing Protection with Comfort

While these ratings provide a guideline, it is essential to balance the level of protection with comfort and dexterity. CutPRO® offers a range of products that not only meet these rigorous standards but also ensure wearer comfort, which is vital for compliance and effectiveness.

A Comprehensive Approach to Safety

By understanding both ANSI and EN 388:2016 standards, you can make more informed decisions about the protective gear needed for your specific environment. CutPRO®'s range offers products that adhere to both these essential standards, ensuring a comprehensive approach to safety in your workplace.

If you are not sure what cut levels your company requires or want further detail on how our garments can assist safety in your workplace, please do get in touch via the button below.

About the Author

The company’s Founder and CEO Robert Kaiser is an expert in personal safety for women and author of the 530-page book NEVER A VICTIM – The Definitive Guide to Women’s Safety, the result of over three decades of dedicated research and experience in understanding both physical and sexual violence against women. This indispensable resource will empower all female readers with the knowledge and confidence to trust in their instincts and innate ability to protect themselves. If you want to better understand the roots, impact, and urgent challenges of this global crisis of violence against women, I recommend reading my article on what is gender-based violence.